Engineering Division (MICCO)

Engineering Division (MICCO)

Introduction

Engineering Division of Gillanders Arbuthnot & Co. Ltd. known as 'MICCO', originally set up in Kolkata in the year 1957 as a steel work fabrication and erection company, has grown into a

leading EPC/Turnkey Constructing company, executing turnkey contracts all over India.

MICCO is a premier project execution company involving design, detail engineering, manufacture and supply of equipment, electrical, instrumentation, erection, commissioning and performance

tests in the field of Building & Technological Structure, Tankage, Piping, Blast Furnace, Re-Heating Furnace, Industrial Furnace, Cold Rolling Mill, Continuous Casting Machine, Gas holder, Coke

Oven Battery project, Raw Material Handling etc.

Design & Drawing

MICCO's drawing office situated at their registered office at B1/3, Gillander House; 8, N. S. Road, Kolkata - 700 001 is fully computerized having latest AUTO CADS,CAESER-II, STADDPRO, Primavera Software,

& engaged in Design drawing work as well as detail work for most of their clients & consultants including Dasturco, MECON, EIL, DCL, TPE, CET, SAIL, Clayton Walker, Bricmont, RAD-CON, Kuettner,

JSW, JSL, JSPL, BSL, BPSL, RINL etc.

LSTK / EPC Contracts

One of the core competences of MICCO is in the area of LSTK and EPC contracts. Here the company's philosophy has been to provide the customer not only turnkey construction but also turnkey

solutions.

GAS HOLDER

MICCO is the exclusive Indian Partner of M/s. Motherwell Bridge Ltd., Clayton Walker Gas Holder, U.K. the world leader for all types of Gasholder Technology. MICCO has executed a numbers of

Gasholder projects during the last over 25 years. These include engineering, fabrication, erection, testing and commissioning.

2 Nos. 150,000 Cu.M. B.F. Gasholders for Tata Steel Ltd.-one each for their Jamshedpur & Kalinganagar Plant, which are the largest Single Dry Seal Gasholder of the world.

1 No. 100,000 Cu.M.Single Dry Seal type LD Gasholder for Tata SteelLtd, Jamshedpur.

1 No. 100,000 Cu.M. Single Dry Seal type Corex Gasholder for JSW Ltd, Bellary.

1 No. 100,000 Cu.M.Single Dry Seal type BF Gasholder for Bhushan Steel Ltd., Angul.

1 No. 80,000 Cu.M. Double Dry Seal type LD Gasholder for Vizag Steel Plant.

4 Nos. 80,000 Cu.M. Single Dry Seal type LD Gasholders-one each for Tata Steel Ltd., Jamshedpur & Kalinganagar, Vizag Steel Plant & JSPL, Angul.

3 Nos. 50,000 Cu.M. Single Dry Seal type BF Gasholder 2 Nos. for JSW Ltd, Bellary & 1 no. for Bhushan Power & Steel Ltd, Jharsuguda.

1 No. 50,000 Cu.M. Single Dry Seal type LD Gasholder for Rourkela Steel Plant.

1 No. 50,000 Cu.M. Single Dry Seal type CO Gasholder for Bhushan SteelLtd, Angul

1 No. Double Dry Seal type LD Gasholder of 80,000 Cu.M. for Vizag Steel Plant.

1 No. 100,000 Cu.M. MAN Oil Seal type CO Gasholder for Rourkela Steel Plant.

On Going Projects

Single Dry seal Gasholders under Construction are

1 No.100,000 Cu.M. LD Gasholder for Bhushan Steel Ltd., Angul. This is being commissioned in record time and before the scheduled completion period.

3 Nos. 80,000 Cu.M. Single Dry Seal type LD Gasholder, one each for Bhilai, Bokaro & NMDC Steel Plant.

1 No. 60,000 Cu.M. LD Gasholder for Tata Steel Ltd., Jamshedpur.

MICCO-MBL has also developed special expertise for repair / revamping of gasholders during short shutdown periods.

This special expertise was used for clients like Durgapur Steel Plants, TATA Steel and Visakhapatnam Steel Plant for their 50,000 Cu. M. Tar Seal type CO Gasholder, 50,000 Cu. M. Dry Seal

LD Gasholder & 80,000 Cu. M. Double Dry Seal Gasholder respectively for repair / revamping work and conversion of 50,000 Cu. M. Klonne Gasholder to 34,500 Cu. M. Single Dry Seal type CO

Gasholder.

MICCO-MBL has also developed special expertise for safe & methodical dismantling of old existing/damaged Wiggins dry seal type gasholder as well MAN Oil/Tar Seal gasholders. They have dismantled

one 100,000 m3 MAN Oil seal type BF Gasholder at Durgapur Steel Plant and one each 80,000 m3 & 50,000 m3 dry seal gasholders and one each 150,000 m3 & 50,000 m3 MAN oil / tar seal gasholders for

Tata steel, Jamshedpur.

BLAST FURNACE

MICCO continues to be forerunner in undertaking any Blast Furnace project in India, from erection of new ones to rebuilding or relining existing ones.

RINL Visakhapatnam Steel Plant ; BF-1 ; Category-1 Repair and Up gradation of 32,000 m3 to 38,000m3 capacity in Association with Siemens VAI, where MICCO also executed the total Water System.

JSW-Bellery; BF-1 ; Revamping & Up gradation from 1209 m3 to 2503 m3 covering dismantling and removal of existing entire shell by Strand jack arrangement, erection of entire blast Furnace, Dust Catcher, Slag Granulation Plant, Top Charging Equipment, Cast House, Charging Conveyor etc. in Module form in 90 Days shutdown period in the year 2016.

Site fabrication of structural & erection of Structural and Equipment for 2015 m3 new Blast furnace at Bhushan Power & Steel as per Paul Wurth technology.

Assembly & Erection of 1008 m3 New Blast furnace at Bhushan Power & Steel Ltd in association of SSIT, China.

Rebuilding & Upgradation of Blast Furnace no-3 of 1400 Cu. M. capacity by changing the shell at Durgapur Steel Plant done by MICCO in record time in association with Mecon. MICCO fabricated, supplied, erected & commissioned total building structure & technological structures along with all mechanical equipment, piping, cast house, gas cleaning plant ,stove renovation, ancillaries, material handling etc.

Fabrication, supply, erection, testing & commissioning of 215 M3 new Blast Furnace for Neo Metalics as per Tata Korf drawing.

Originally the 1600 m3 G-Blast furnace of Tata Steel, Jamshedpur which came in piece small from Portugal was assembled & erected by MICCO.

MICCO supplied over 5000 MT technological structures for Durgapur Steel Plant's Blast Furnace No.4.

REHEATING FURNACE / INDUSTRIAL FURNACE

MICCO is having total solution for various furnaces and heating system for steel rolling mills, aluminium and copper industry as well as for different heat treatment and other

heating appliances.

MICCO has an exclusive Tie-up with M/s. Andritz Metals Inc., Germany (Formerly Bricmont Inc. USA) in the area of Reheating Furnace like Walking Beam, Walking Hearth, Pusher, Tunnel and Roller

Hearth etc. MICCO also has association with M/s RAD-CON Inc, USA in the field of Bell Type Annealing Furnaces.

Design, Fabrication, Supply, Erection, Testing & Commissioning of Reheating furnaces -

150 TPH Walking Beam type Reheating Furnace for Rebar Mill in Tata Steel Ltd, Jamshedpur.

110 TPH Walking Beam type Reheating Furnace for Billet Mill in Durgapur Steel Plant, Durgapur.

160 TPH Walking Beam type Reheating Furnace for Bar Mill in IISCO Steel Plant, Burnpur.

180 TPH Walking Beam type Reheating Furnace for Universal Section Mill in IISCO Steel Plant, Burnpur.

150 TPH Walking Beam type Reheating Furnace for Wire Rod Mill in IISCO Steel Plant, Burnpur.

160 TPH Walking Beam type Slab Reheating Furnace for Stainless Steel Hot Strip Mill in Bhuvee Profiles & Stainless Pvt. Ltd., Angul.

220 TPH Walking Beam type Reheating Furnace for Medium Structural Mill in Durgapur Steel Plant, Durgapur.

MICCO in association of M/s. Radcon Inc, USA & M/s. Sunag Engineering, Kolkata did the Design, Fabrication, Supply, Erection, Testing & Commissioning of Hydrogen Bell Annealing Furnace consisting

of 47 Nos. Bases for New Cold Rolling Mill in Bokaro Steel Plant.

MICCO in association of Beijing Shenwu successfully did the Erection, Testing & Commissioning of BF Gas operated 300

TPH Walking Beam Regenerative type Reheating Furnace for Hot Strip Mill in Tata Steel Ltd., Jamshedpur.

MICCO has also fabricated and supplied different Technological Structures for the following furnaces:

250 TPH Tunnel Furnace for Bhusan Steel.

250 TPH Walking Beam Slab Reheating Furnace for Tata Steel Ltd. Jamshedpur.

300 TPH Walking Beam Slab Reheating Furnace for Essar Steel and Jindal Vijaynagar Steel Ltd.

Two Nos. 300 TPH Walking Beam Slab Reheating Furnace for Bokaro Steel Plant, Bokaro.

In the area of LADLE and other furnace, MICCO has successfully completed the following :

Fabrication and supply of different mechanical components of Electric Furnace for G.A. Danieli, Kolkata.

50T Electric Arc Furnace for Llyod Steel.

Fabrication, Supply and Erection of Shoe Pusher Furnace Components for Bharat Aluminium Company, Korba.

Fabrication, Supply and Erection of complete continuous galvanising line furnace of Tata Steel Ltd.-CGL#2.

Furnace For Non-Ferrous Material.

Copper Smelting, settling and converting furnace for Birla Copper, Dahej including detailed engineering fabrication and erection. The technology was provided by Ausmelt, Australia.

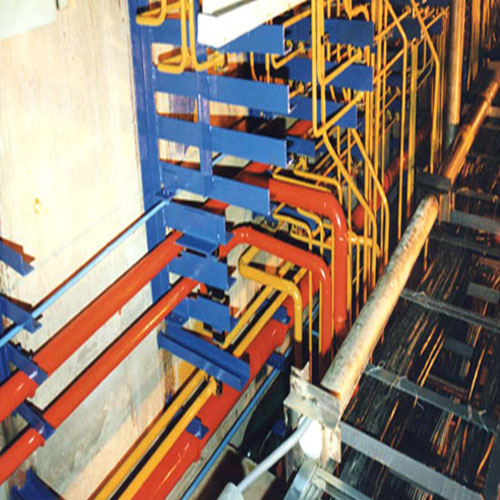

PIPING

Piping is a critical thrust area for MICCO in both above ground and underground piping. MICCO has expertise in CS, SS, AS, IBR and Rubberised piping work.

Refinery Piping at Digboi for IOCL.

High Tensile Piping for Vizag Steel Plant.

Coke Oven Gas Piping and steam piping for Gas Mixing Station for Tata Steel.

Skin Pass Mill, Hydraulic and Lub Piping for Tata Steel.

Hydraulic/Grease/Lub Piping for HSM at Rourkela Steel Plant.

CS/SS Piping for continuous casting granule plant for Stollberg Durgapur.

Overhead Yard Pipe Work for 1MTPA Expansion Project at Tata Steel.

CS/SS Piping Work for Water System of G Blast Furnace at Tata Steel.

SMS 1 & II, LD Yard Piping for JSW.

LD Piping for VSP, SMS II & Bokaro Steel Plant SMS II Gasholder Project.

LP Piping for Power Plant at Bakreswar and Mejia.

Piping work for Slab Caster, Bloom Caster, Billet Caster at Tata Steel & Vizag Steel.

B. F. Gas duct work at Bokaro Steel Plant.

BOF Gas duct work at Vizag, Bokaro and Tata Steel Plant.

Total water system piping for Capital repair of RINL BF-1 & BF-2 Pump house of Capital Repair of RINL, BF-1&2.

Total Piping work of Capital Repair of RINL BF-1, Tata Steel "E" Blast furnace.

External Water supply system for Bloom Cum Round Caster and LF#3 at SAIL Durgapur steel plant.

STRUCTURAL STEEL WORK.

MICCO is an established leader in structural steel work fabrication and erection and have executed more than 300,000 MT of work. Some of MICCOs major works have been for different

core sectors like the Power, Steel Copper, Aluminium, Paper etc as below:

Power

WBSEB - Bandel 4000 MT.

WBSEB - Kolaghat through BHEL 5000 MT.

Steel Plant

Raw Material Storage & handling system for Sinter Plant No.3 of Bhilai Steel Plant - 9000 MT.

CRM Building for Tata Steel Ltd. - 5000 MT.

RMBBS Area, 6th Lime Kiln, Coal Injection System for Tata Steel Ltd. - 6300 MT.

H.S.M. for Tata Steel - 11,000 MT.

LD-1 Building for Tata Steel - 13400 MT.

Bokaro Steel Plant - 22000 MT.

Rourkela Steel Plant - 16000 MT.

Blast Furnace Structural for DSP - 2500 MT.

Bhushan Steel Ltd. - 5000 MT.

Bhushan Steel & Power Ltd. - 8000 MT

JSW-Bellary -12,500 MT.COBP RINL 1000 tonnes

Aluminium Plant

NALCO, BALCO, HINDALCO - 40000 MT.

Export

Fabrication and supply of Building Structural for CRM Projects and Cement Plants more than 18000 MT. to Bangladesh, Nigeria, Zambia.

Fabrication & supply of Building Structure for Ferrochrome Projects more than 2000 MT. to South Africa.

CONTINUOUS CASTING MACHINE

Molten metal from Steel Melt Shop is the feed material for Continuous Casting of Billets, Blooms and Rounds. These are then sent to various Rolling Mills for subsequent processing.

In technical association with Danieli India & Danieli Italy, MICCO has commissioned plant & equipment like Roller Tables, various structural steel work and Piping System for water, gas, compressed

air, hydraulic and grease system.

MICCO has erected & commissioned the entire mechanical & electrical equipment for the following jobs:-

Continuous casting Machine at Tata Steel, one four strand Billet Caster (supplied by Siemens VAI).

Six strand Billet-cum-Bloom Caster for VSP - 3 nos.

Four strand Bloom-cum-Round Caster for DSP - 1 no.

STRUCTURAL MILL

Structural Mill is a non-flat Rolling Mill designed for producing Beams, Channels, Angles, Flats, Squares and Rounds which are most important input for construction industries.

The feed material to this mill is Continuous Cast Blooms which are reheated in Reheating Furnace and rolled in this mill.

MICCO as Consortium Partner of Danieli India and Danieli Italy and have successfully executed the project for supply of Structural Mill in RINL Vizag Steel Plant where M/s Micco have

supplied entire pipeline for water, gas, hydraulics and lubrication system and did complete erection of structural, mechanical and electrical plant & equipment.

Project Executed

40 TPH Evaporation Plant at Bharat Aluminium Co. Ltd. Korba, M. P.

Phenolic Sewerage Treatment Plant, Bhilai Steel Plant.

Gas Producer Plant at Bharat Refractories Bhilai.

Starch Solution Preparation Plant at Stollberg, Durgapur.

Equipment of By-Products & Plant Utility Services for COBP at Jindal Stainless Ltd, Duburi.

Tar & Liquor separation system with Decanter at Sail- Durgapur Steel Plant.

COKE OVEN BATERY

Project Executed

Erection and commissioning of Plant & Equipment, Piping, Refractories etc. for rebuilt of recovery type C.O. Battery No. 10. at ISSCO Steel Plant, Burnpur, West Bengal.

Erection and commissioning of Plant & Equipment, Piping, Refractories etc. for rebuilt of recovery type C.O. Battery No.2. at Sail Durgapur Steel Plant.

Fabrication & erection of piping , technological structures & equipment for Hooghly Met Coke non-recovery type C.O. Battery.

MICCO is the pioneer in the field of Electrostatic Precipitator assembly, fitting, erection including all structural, mechanical and electrical work, testing and commissioning. Some of MICCO's

clients in this field are Tata Steel, RINL, Sail Bokaro, Bakreshwar TPS, Mejia TPS, Sambalpur TPS etc.

DESULPHURISATION

The hot metal treatment for desulphurisation takes place before the hot metal is charged to the basic oxygen furnace for making liquid steel. With requirement of stringent quality steel, hot

metal desulphurisation before steel making is gaining importance and more and more steel plants are adopting this process.

With technology supply from M/s.Kuettner GmbH & Co.KG, Germany, MICCO has executed three hot metal Desulphurization Plants at LD Shop-1 and LD Shop-2 of Tata Steel Limited. Except few critical

equipment, the entire supply was carried out independently.

POWER DISTRIBUTION SYSTEM

MICCO is executing a project at RINL - Visag Plant for supply and services for Power Distribution System for Coke over 5 and By Product project along with Daniele India Ltd, as

consortium partner. This project covers the design, manufacturing, testing at works, packing, supply, storage and handling at site, erection, testing, relay setting/relay coordination,

commissioning, including related civil and structural design, construction/modification work and handing over in "ready to switch on" condition to the purchaser of the integrated power

distribution system with all the power distribution equipment's & their auxiliary facilities required for Coke oven 5 and its related Coal handling, CDCP, Coke handling, By Product

plants and Power evacuation of 14 MW Power Plant Projects (COBP 5 Project) of RINL - Visakhapatnam Steel plant on a turnkey basis. This is an ongoing project and will be commissioned

in 2019, the civil volume of this project is 11000 cubic metre and 1000 tonnes of structures.

JSW Dolvi

MICCO has started the project in the JSW Dolvi plant for rolling, fabrication, erection, alignment and commissioning of cyclone and auxiliary equipment.

CLIENTS

The Company has an impressive record of completing EPC projects in record time in no of times and its rich clientele and technology providers have always reposed the faith and trust on

MICCO during the last 30 years .

Steel Plants

SAIL Plants - Durgapur, Bokaro, Bhilai, Rourkela, Iisco, Salem.

RINL, Vizag Steel Plant.

Neelachal Ispat Nigam Ltd, Jajpur.

Tata Steel Plant, Jamshedpur & Kalinganagar.

JSW Plant, Bellary & Dolvi.

Bhusan Steel Ltd, Angul.

Bhusan Power & Steel Ltd, Jharsuguda.

NMDC Steel Plant, Jagdalpur.

Jindal Steel & Power Ltd, Angul.

Non Ferrous

Balco, Nalco, Hindalco (Renukut), Birla Copper (Dahej)

Power

BHEL,WBSEB

Others

HZL, HEC, DANIELI, OCL, L & T, MECON, PRIMETALS, SMS.

COLLABORATION / TIE UP / ASSOCIATION

Being always on the lookout for the latest technology, MICCO has associations / tie-ups with a numbers of overseas technology providers as-

Motherwell Bridge Ltd, Clayton Walker Gasholders, UK.

Andritz Metals Inc, India and Austria.

RadCon Inc, USA.

Primetals Technologies, Austria, Germany & India.(erstwhile Siemens VAI)

Danieli, Italy & India.

SMS, Germany & India.

TPE, India & Russia.

These associations have enhanced MICCO's capability of upgrading quality standards and minimizing costs.

QUALITY POLICY

We, at Gillanders Arbuthnot & Co. Ltd: Unit- Modern India Construction Company committed to total Customer satisfaction by providing Products & Services which meet or exceed Customers

contractual expectations in term of quality & time . Our Products & Services should be a benchmark & create a recommendation for future business. All our commitments, actions and Products

must be recognized as an expression of quality. We shall also stay focused continuously and meet the changing needs of the industries. We shall imbibe a better work culture in all employees

through systems. We shall generate and sustain the conviction in all employees and management that intended Quality has to be achieved and continually improved.

This policy requires that all people of GACL-MICCO be committed to excellence and do the work right- the first time every time.

Our objective is to build quality into operations to ensure zero defect products and services and to achieve excellence in all endeavors and have satisfied customer.

HEALTH, SAFETY & ENVIRONMENT (HSE) POLICY

MICCO has committed to provide a safe and healthy work place and environment for all of our staff, employees and our Contractors' employees and workmen to ensure the operations being carried

out in a manner which protect the health, environment and community in all our running sites at Tata, RINL, JSW, JSPL, SAIL, NMDC, Bhushan Steel amongst others.

Philosophy

All accidents are preventable.

No task is so important that risk of injury to people or damage to the environment is justified.

HSE complied with all applicable legislation.

Identifying and eliminating/controlling hazards and pollution that could cause accidents, illness or environmental harm by indicating HSE procedures to the

employees and workmen who would aspire to adopt the same standard in all of their work.

Deputation of safety officer at all the sites and maintenance and studying of safety manuals at the running sites.

Continuous training of safety for the workmen and officers engaged at site through our safety officers.